John Deere 5100ML Low-Profile Utility Tractor

Agriculture

- Low profile hood design for visibility and access to hard-to-reach areas

- 99 hp John Deere PowerTech™ engine is emissions compliant and performs regeneration automatically for maximum uptime

- 16F/16R PowrReverser™ transmission for easy, clutch-free forward and reverse

Featured List

- Rated PTO HP: 85 (59.7 kw)

- 2WD or MFWD: MFWD

- Low Clearance Cab: NA

- Low Profile Open Station: Yes

- Engine HP: 99 (73.8 kw)

Featured Content

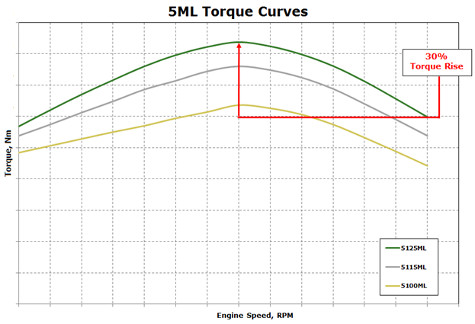

Putting more power to the ground translates to increased productivity in demanding conditions. Simply put, torque is the useable power that can be achieved. More torque leads to more lugging ability which helps the operator be more productive.

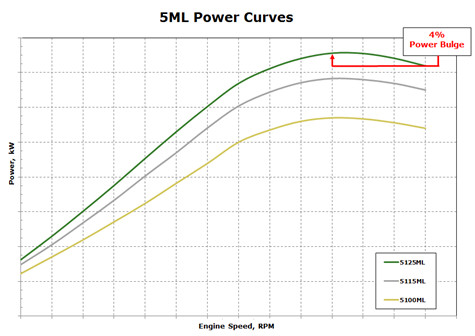

5M Final Tier 4 (FT4) engines feature up to a 4 percent power bulge when put under load. The power bulge feature of the electronically controlled engine delivers additional horsepower as engine rpm drops below rated speed. Additionally, a 30 percent torque rise provides the force that maintains horsepower as engine rpm drops below rated speed.

When the tractor is under load, power bulge and torque rise work together to get through the tough spots without having to downshift. Horsepower and torque are mathematically related.

|

As rpm drops, the only way to maintain or increase horsepower is to provide additional torque. The output horsepower is greater than or equal to rated horsepower as the engine is pulled down to 1750 rpm.

The peak torque rise also occurs near the rated economy power take-off (EPTO) speed.

5ML power curve summary

5ML torque curve summary

The PowrQuad™ transmission can be ordered on any of the 5ML Tractor models with three different options to meet producer needs: 16F/16R PowrQuad, 16F/16R PowrQuad with creeper, or 32F/16R Power 8. These three transmissions options come standard with a 540/540 Economy/1000 power take-off (PTO) and are compatible with the pressure-and-flow compensated (PFC) hydraulic system.

Pairing a PowrQuad or a Power 8 transmission with PFC hydraulics provides more hydraulic flow, increased hitch lift capacity over PowrReverser models, and an electrohydraulic (EH) hitch control for repeatable hitch movements.

The ergonomically placed transmission control allows the operator to change gears and ranging with one simple control. Two buttons, a rabbit or turtle indicator, allow one to gear up (rabbit) or gear down (turtle) within a range. A range change can be made with a simple press of the declutch button rather than using the foot clutch. If preferred, the foot clutch remains incorporated into the operator station for use.

Integrated declutch and gear buttons on transmission control

Ranges on the transmission control can be selected by moving the controller in an H pattern. The lever selects ranges A, B, C, or D. Ranges C and D are fully synchronized. That means, when upshifting, operators can move from range C to D without stopping the tractor. On the downshift, operators can move from D all the way to B without stopping.

Maximum productivity is achieved with clutchless hydraulic shifting between forward and reverse and is ideal for loader work and any other applications that require frequent directional changes in tight spaces. An electrohydraulic fingertip directional lever control allows the operator to effortlessly switch directions with a small finger motion.

This control is located on the left side of the instrument console and selects forward, reverse, and neutral positions. It also allows the operator to steer and shift direction with the left hand, freeing the right hand to operate other tractor controls, such as the loader, rear implements, or hand throttle.

NOTE: A neutral start switch requires the directional lever be in the neutral position to start the engine.

PowrQuad transmissions include:

- Wet clutch

- Ergonomically mounted transmission lever controlling both gear and range changes

- Declutch button on the range lever

- Left-hand reverser

- Constant-mesh, helical-cut gears

- Pressure-lubricated top shaft

- Positive park pawl

- Three-speed PTO

- Neutral start switch

Reversible stub shaft

All 5ML Tractors equipped with a PowrQuad or Power 8 transmission have a reversible stub shaft with six splines and 21 splines (38 mm [1.5 in.]). To switch between 540 and 1000 speeds, simply remove the snap ring, flip the PTO shaft, and reinstall the snap ring. The tractor PTO operates at 540-rpm speed when the six-spline end of the shaft is visible, and at 1000 speed when the 21-spline end of the shaft is visible.

The reversible 540/ 540E/1000 PTO stub shaft is located in a dry cavity to allow changing from 540/540E rpm to 1000 rpm or vice versa without any oil spillage. This interchangeability allows the matching of different implements. The reversible stub shaft improves uptime as no bolts are needed for removal, just a simple snap ring.

|

|

A = snap ring B = snap ring groove C = bore |

| Reversible stub shaft (six and 21 splines) | ||

NOTE: See PTO functional area for more information on economy PTO.

The PowrReverser transmission provides 16F/16R speeds. This transmission comes standard with a dual-speed 540/540 Economy power take-off (PTO) and is ideal for applications requiring frequent directional changes.

Hydraulic wet forward and reverse clutches maximize durability and outlast the life of any dry clutch. When tractors are run by multiple operators with a variety of experience levels, a wet clutch is the best way to maintain transmission integrity and performance while decreasing clutch replacement costs.

Two platform-mounted levers offer easy and comfortable shifting for a pleasant operator experience. The gear-shift lever is easy to reach and the less-used range lever is shorter. Unique knobs make it easy to distinguish between the two. Also incorporated into the gear shift lever is the declutch button. No foot clutching is required to shift between gears within a range.

NOTE: The PowrReverser transmission is not available for the 5125ML tractor.

Integrated declutch button on gear shifter

The forward lever, or gear shifter, selects one of four speeds, all which are synchronized shifts for on-the-go shifting with the use of the clutch or declutch button. The rear lever selects ranges A, B, C, or D. Ranges C and D are fully synchronized. That means, when upshifting, operators can move from range C to D without stopping the tractor. On the downshift, operators can move from D all the way to B without stopping.

Maximum productivity is achieved with clutchless hydraulic shifting between forward and reverse and is ideal for loader work and any other applications that require frequent directional changes in tight spaces. An electrohydraulic fingertip directional lever control allows the operator to effortlessly switch directions with a small finger motion.

This control is located on the left side of the instrument console and selects forward, reverse, and neutral positions. It also allows the operator to steer and shift direction with the left hand, freeing the right hand to operate other tractor controls, such as the loader, rear implements, or hand throttle. The PowrReverser transmission has a built-in engagement override valve for additional safety. This valve requires the clutch pedal to be depressed one time after each engine start before the transmission will begin to operate normally, giving the operator another opportunity to put all focus on the tractor.

NOTE: A neutral start switch requires the directional lever be in the neutral position to start the engine.

The speed of directional changes can be adjusted to the operator’s preference or application demands with the field-installed infinitely variable control kit.

The 16F/16R transmission includes:

- Wet clutch

- Platform-mounted shift levers (four gears, four ranges)

- Declutch button on the gear lever

- Left-hand reverser

- Constant-mesh, helical-cut gears

- Pressure-lubricated top shaft

- Positive park pawl

- Neutral start switch

All tractors have economy PTO (E-PTO), a fuel saving feature that allows producers to operate rear implements at 540 PTO rpm but at lower engine rpm. The result is lower engine vibration, reduced noise, less wear and tear on the engine, reduced fuel consumption, and increased operator comfort.

NOTE: See PTO functional area for more information on E-PTO.

The standard OOS on 5ML Tractors was designed for low-clearance applications. It features a low-profile seat, a smaller-diameter steering wheel, protected controls, and a low-profile, rear-mounted rollover protective structure (ROPS). Combined with the sloping hood, this is beneficial to the operator’s visibility to the front of the tractor. Rounding off these standard features and incorporated into each operator platform is a shield which limits heat transfer from the hydraulics to the operator.

All of the most crucial operator controls are conveniently located within arms’ reach on the right-hand console control pod. The engine throttle control, selective control valve (SCV) levers, power take-off (PTO) engagement, and hitch-lift control levers are grouped together. On the 5ML, this control pod is positioned on the right-side fender, protected from low-hanging crops by a shield.

Right-hand fender shield and low profile seat

Color-coded bands on the SCV levers correspond with the color on the rear SCVs, making it easy for any operator to determine which lever operates which rear SCV.

The 5ML Tractor also offers optional fender extensions to minimize crop disturbance, especially in orchards or tree nut applications. Two fender extension options are available to meet varying tire sizes and coverage preferences.

The foldable ROPS on the 5ML Tractor has a unique design and is 15.2-cm (6-in.) lower at maximum height than the standard 5M Tractors.

The shifter linkages are tighter to offer a more accurate shift pattern, which translates to a crisper throw between gears. Incorporating technology found on standard 5M Tractors, the 5ML now offers a declutch button, enabling the operator to shift gears within a range without the use of the foot clutch.

Dash details:

- Cluster

- Controls

- Steering wheel

5ML Tractors also include the following features:

- Retractable seat belts

- Rear certified ROPS for OOS tractors

- Heat shield limiting hydraulic heat passed onto the operator

- Key-switch interlock prevents bypass starting

- Audible and visual PTO warning alerts when the operator leaves the seat with the PTO engaged

- Positive park position prevents the tractor from moving when the engine is off

- Four amber turn-signal/flashing warning lights for road transport (these are break-away)

- Slow-moving vehicle (SMV) sign alerts other road users during transport

- Safety decals keep safety in the minds of new and experienced operators

- Left- and right-hand steps provide easy and convenient access from both sides of the tractor

- Fuel system is fully grounded to meet safety and fuel fill regulation requirements

- For convenience of operation, the fuel and diesel exhaust fluid (DEF) fill are both on the same side with clearly marked and color coded caps. The DEF tank has a capacity of 12.1-L (3.2 gal.), which is more than enough to sustain proper tractor operation and fuel treatment for more than one full tank of diesel. A field-installed lockable fuel cap is offered for protection and peace of mind.

Transmission controls on PowrReverser™ transmission models:

Gear and range shift levers are located to the right of the operator. The gear lever incorporates a declutch button enabling the operator to shift gears without the use of the foot clutch. Unique knobs also make it easier to distinguish between the two.

Gear lever with declutch button

Transmission controls on PowrQuad™ transmission models:

A single transmission control is located to the right of the operator. This control features the ability to shift through gears within a range using the rabbit button to increase gears and the turtle button to decrease gears. A range change can be completed with this control, as well by moving through A-D ranges similar to a traditional range controller. To aide in ease of operation, operators can use the integrated declutch button rather than the foot clutch to change ranges.

Transmission control on PowrQuad transmission models

A foot throttle with a platform pedal is located on the right side of the operator. The pedal is positioned for ease of use, yet does not clutter the floor. The hand throttle is easily accessible on the right hand console.

Engaged by either foot, the differential lock pedal is placed on the floor.

Hydraulics controls

The color-coded bands on the levers, which control triple rear SCVs, correspond to the color of the dust cap and the SCV valve they control.

Differential lock button

When the tractor is used in applications requiring the clutch and brake pedals to be used frequently, the operator will see the benefit of the suspended pedals.

The electrohydraulic forward/reverse direction lever is located on the left-hand side of the instrument console, connected to the steering column. There is also a guard for the reverser lever. Operated with the left-hand finger, the right hand is free to simultaneously run the loader, hitch, or hand throttle.

Left hand reverser with guard

3-point hitch controls

Mechanical hitch controls are available on models equipped with a PowrReverser transmission, while models equipped with a PowrQuad transmission will have an electrohydraulic (EH) hitch. With an EH hitch, operators will have the functionality to raise and lower the hitch from the rear left-hand fender, reducing time when attaching and detaching implements.

Left-hand fender hitch control

PTO controls and speeds

The 5ML features electrohydraulic PTO engagement on all models.

The push/pull knob on open station tractors is conveniently located beside the hand throttle on the right-hand side of the operator. When the PTO is engaged, a light on the instrument panel will illuminate and PTO speed is indicated by target bars. Models equipped with a PowrReverser transmission have a 540/540E rpm shiftable PTO while models equipped with a PowrQuad transmission have a three-speed PTO, 540/540E/1000 rpm.

Enhancing operator safety, the tractor does not start with the PTO engaged. An alarm sounds if the operator attempts to leave the seat with the PTO engaged. The PTO shaft is protected by a hinged shield.

Mechanical front-wheel drive (MFWD) controls

All four-wheel drive (4WD) axles are equipped with the engage-on-the-go MFWD. This toggle switch is now located on the right-hand console.

Lighting controls – Multi-position dial

The five-position lighting package is straightforward with the lighting control switch on the right side of the steering column. The switch positions are: off, warning, work light, transport 1 (warning and high-beam headlights), and transport 2 (warning and headlights). A turn-signal lever is located on the left side of the steering column for quick and easy use.

| Transmission - Clutch; Wet/Dry | Wet |

|---|---|

| Rear hitch - Remote control valves available | Standard: three |

| Rear axle - Differential controls | Electrohydraulic |

| Engine performance - Rated power | At 2,200 per ISO 97/68/EC: 74 kW 99.1 hp |

| Rear hitch - Maximum lift capacity behind lift points | Standard: 2223 kg 4900 lb Optional: 2565 kg 5654 lb Optional with PowrQuad: 3164 kg 6975 lb Optional with PowrQuad: 3569 kg 7868 lb |

| Rear hitch - Sensing type | Top link |

| Engine specifications - Cylinders liners | Wet sleeved |

| Hydraulic system - Available flow at a single rear SCV | Standard: 70 L/min 18.4 gpm Optional: 100 L/min 26.4 gpm |

| Transmission - Creeper | 16F/16R PowrQuad with creeper |

| Capacities - Fuel tank | Standard: Open: 112 L 29.5 U.S. gal. Optional (PowrQuad models): 144 L 38 U.S. gal. |

| Rear axle - Type | Inboard planetary |

| Rear power take-off (PTO) - Type | Standard: 540/540E Optional: 540/540E/1000 |

| Rear axle - Brakes, type and control | Hydraulic wet disc |

| Rear hitch - Hitch draft control load sense type | Standard: Mechanical Optional: Electrohydraulic |

| Capacities - Diesel exhaust fluid (DEF) tank | 12 L 3.2 U.S. gal. |

| Rear power take-off (PTO) - Engine rpm (at rated PTO speeds) | 540 at 2100 rpm 540E at 1645 rpm 1000 at 2103 rpm |

| Engine specifications - Engine family | FJDXL04.5211 |

| Dimensions - Wheelbase | 2350 mm 92.5 in. |

| Hydraulic system - Type | Standard: Open center Optional: Pressure-and-flow compensated (PFC) system |

| Rear axle - Axle type | Flanged |

| Dimensions - Approximate shipping weight, Open;Cab | PowrReverser models: Open: 3764 kg 8298 lb PowrQuad models: Open: 3975 kg 8740 lb Cab: Not applicable |

| Transmission - Reverser | Yes |

| Hydraulic system - Joystick SCV control | Optional |

| Engine specifications - Displacement | 4 cylinders: 4.5 L 276 cu in. |

| Hydraulic system - Pump rated output | Standard: 94 L/min 24.7 gpm Optional: 117 L/min 31 gpm |

| Engine specifications - Aspiration | Turbocharged |

| Rear hitch - Hitch category (SAE designation) | Category 2 |

| Rear power take-off (PTO) - PTO actuation | Electrohydraulic |

| Operator station - Rollover protective structure, OOS | Rigid - foldable - telescopic Foldable, two-post Platform - flat/straddle Flat Gearshift location - console/floor Floor |

| Key Specs - Rated PTO power (hp SAE) | At 2,100 per SAE: 63 kW 85 hp |

| Engine performance - Rated PTO power (hp SAE) | At 2,100 per SAE: 63 kW 85 hp |

| Tires - Turning radius without brakes | 3.8 m 12.5 ft |

| Key Specs - Rated engine power | At 2,200 per ISO 97/68/EC: 74 kW 99.1 hp |

| Engine specifications - Description | John Deere PowerTech™ 4045 engine |

| Tires - Front | 12.5/80 - 18 In. I3 Bias |

| Key Specs - Transmission type | Standard: 16F/16R PowrReverser™ Optional: 16F/16R PowrQuad™ 16F/16R PowrQuad with creeper 32F/16R PowrQuad |

| Key Specs - Engine displacement | 4 cylinders: 4.5 L 276 cu in. |

| Tires - Turning radius with brakes | 3.34 m 11 ft |

| Key Specs - Hydraulic pump rated output | Standard: 94 L/min 24.7 gpm Optional: 117 L/min 31 gpm |

| Electrical system - Type of bulb in beacon (Halogen, Zenon, LED) | |

| Operator station - Seat | |

| Hydraulic system - Number of mid selective control valves (SCVs) | Zero; up to two |

| Hydraulic system - Number of rear selective control valves (SCVs) | Standard: three |

| Tires - Rear | 19.5L - 24 In 10PR R4 Bias |

| Tires - Wheel tread range | Front: 1299-1997 mm 51.1-78.6 in. |

| Weight - Base machine weight | |

| Capacities - Cooling system | |

| Key Specs - Engine description | John Deere PowerTech™ 4045 engine |

| Transmission - Type | Standard: 16F/16R PowrReverser™ Optional: 16F/16R PowrQuad™ 16F/16R PowrQuad with creeper 32F/16R PowrQuad |

| Key Specs - Rear hitch category (SAE designation) | Category 2 |

| Electrical system - Type of bulb in headlight (Halogen, Zenon, LED) |