John Deere 730 Air Disk Drill

Agriculture

- See the flow of seed & fertilizer from the cab with RelativeFlow™ blockage monitoring

- Double-disk openers offer precise depth

- Three tool widths and two seed row spacings

- Field Doc™ and Map-Based Prescriptions

Featured List

- Opener: Double-disk openers

- Transport Width: 16 ft. 3 in., 19 ft.

- Fertilizer Placement: In Furrow

- Working Width: 28 ft., 36 ft., 44 ft.

- Row Spacing: 6 in. (15-cm)

7.5 in. (19-cm)

Featured Content

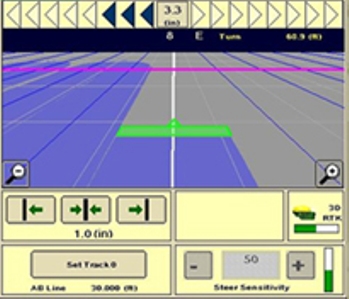

Manual guidance

Manual guidance allows operators to manually steer by matching the machine icon with the line on the screen or by using the path accuracy indicator at the top of the guidance view screen.

Individual press wheel depth adjustment

Depth-gauging press wheels:

- Allow quick, easy opener depth control

- Assist in controlling furrow depth

- Promote positive seed-to-soil contact for good germination

- Adjustments can be made from 0 cm (0 in.) to 9 cm (3.5 in.) by increments of 6 mm (1/4 in.)

5-cm x 33-cm (2-in. x 13-in.) press wheels are available on the 730

5-cm x 33-cm (2-in. x 13-in.) press wheel

5-cm x 33-cm (2-in. x 13-in.) press wheel

For 15.2-cm (6-in.) row spacing:

- 5-cm (2-in.) x 33-cm (13-in.) (A) (standard equipment)

NOTE: 15.2-cm (6-in.) row spacing is not recommended for high-residue conditions or sticky soils like in the Red River Valley of the North.

For 19-cm (7.5-in.) row spacing:

- 5-cm (2-in.) x 33-cm (13-in.) (A) (standard equipment)

730 Level-Lift tilling, fertilizing, and seeding

The 730 Level-Lift Air Disk Drill frame is very similar to the 2210 Level-Lift Field Cultivator. The 730 LL Air Disk Drill is a secondary tillage and seeding tool, an industry exclusive from John Deere. This frame is designed to offer durable support for the double disk openers while providing flexibility over level to gently rolling terrain.

Frame components include:

- Front-mounted rockshaft

- Tube-Thru-Tube frame

- Hose and wiring harness support and protection

Faster working speeds and consistent depth are results of the above features.

The 730 Level-Lift frames are:

- Constructed of continuous five-bar Tube-Thru-Tube frame

- 10.2-cm x 10.2-cm (4-in. x 4-in.) cross members

- 7.6-cm x 15.2-cm (3-in. x 6-in.) centerframe hitch tubes

- 5-cm x 12.7-cm (2-in. x 5-in.) end tubes

The large frame member sizes, joint welds, and the wheel module placement add to the structural integrity, providing stable, consistent front-to-rear and side-to-side operation.

The frame:

- Is 3.4-m (11.2-ft) deep frame (fore-aft)

- Has 61-cm (24-in.) under-frame clearance

- Can handle residue amounts of up to 40 percent

The wings flex 7 degree up and down. They fold over center for a compact transport or storage profile.

The front-mounted rockshaft:

- Offers superior front-frame strength for unmatched side-to-side levelness

- Provides torsional rigidity for the hydraulic system

- Opens up the frame for true shank placement, improving overall residue flow

The TruPosition™ shanks have a trip force at 90.7 kg (200 lb) and a 25.4-cm (10-in.) trip height.

Leading edge cuts through moderate residue levels

Narrow disk angle leaves smooth field finish

The 34.3-cm (13.5-in.) diameter double-disk openers are offset to create a narrow furrow for optimal seed placement. They feature aluminum boots and have a long-arm/short-arm stagger for residue clearance. Either 15.2-cm (6-in.) or 19-cm (7.5-in.) row spacing is available.

NOTE: 15.2-cm (6-in.) spacing is not recommended for heavy, sticky soils such as the Red River Valley of the North.

The 6-mm (1/4-in.) offset creates a leading edge and pinch point that is close to the soil surface for optimal penetration and residue cutting. Alternating of the blades with right and left leading edge prevents side drafting and leaves the field smooth with minimal soil throw.

To win big in small grains, it takes a seeding solution that superseeds your expectations. John Deere delivers with a complete line of everything you need – and the sizes you want – to seed for success. Air-hoe drills. Commodity air carts. No-till air drills. Openers. Fertilizer attachments. Central commodity systems. Box drills. Plus precision ag technology to stretch your productivity to higher levels. But it’s far more than iron and technology. It’s the exceptional agronomic know-how and unsurpassed dealer support in all phases of production to keep you running. With our latest additions to equipment and openers, our seeding solutions deliver the next-generation performance you need to help you reach the full potential of each seed. That’s our commitment to you.

| Sizes - Number of ranks | 4 ranks of c-shanks,1 rank seed openers |

|---|---|

| Sizes - Number of sections | 3 |

| Opener - Penetration force | Patented Active Hydraulic |

| Mainframe - Wing flexibility | 11 degrees up, 9 degrees down |

| Harrow - Type | Tine tooth |

| Harrow - Attachment | Rolling Basket with 1-bar harrow |

| Seeding tool depth control - Type | On individual openers |

| Seeding tool depth control - Range | 1/4 inch increments |

| Tires - Gauge wheels, wing | 2-7.60x15 8PR |

| Tractor hydraulic requirements - Minimum SCVs | 2 SCVs |

| Warning lights - Standard | Yes |

| Freight - Shipping location | Des Moines, IA |

| Key Specs - Opener - Type | Double disk |

| Shanks - Arc | 47 degree |

| Clearance - Between ranks range | 29 to 41-in. (73.7 to 104 cm) |

| Mainframe - Cross tubes | 4x4-in. (102x102 mm) |

| Mainframe - Type | 3-section drawn flexible |

| Shanks - Finishing tool | double bar harrow or rolling basket with single bar harrow |

| Shanks - Type | Tru-Position |

| Key Specs - Number of sections | 3 |

| Mainframe - End tubes | 2x5-in. (50x127 mm) |

| Tires - Castering stabilizer | (2) 7.60x15 8 PR |

| Opener - Size | 13.5-in. (343 mm) with 0.25-in. (6 mm) offset |

| Tires - Centerframe; standard | (4) 11Lx15 Load Range D walk-over tandems |

| Opener - Type | Double disk |

| Tires - Wing; standard | (4) 9.5Lx15 Load Range D walk-over tandems |

| Key Specs - Mainframe - Wing flexibility | 11 degrees up, 9 degrees down |

| Key Specs - Harrow - Attachment | Rolling Basket with 1-bar harrow |

| Shanks - Quantity | 37 |

| Mainframe - Hitch (tubular steel) | 6x10-in. (76x152 mm) |

| Key Specs - Harrow - Type | Tine tooth |

| Clearance - Hydraulics | active hydraulic downpressure |

| Opener - Boot | aluminum |

| Key Specs - Number of ranks | 4 ranks of c-shanks,1 rank seed openers |

| Mainframe - Folding | over-center |

| Key Specs - Seeding tool depth control - Range | 1/4 inch increments |

| Transport position - Width | 16-ft. 3.6-in. (4.97 m) |

| Shanks - Trip clearance | 10 in. 25.4 cm |

| Shanks - Size | 3/4 x 1-3/4 x 24-in. 19 x 44 x 610 mm |

| Opener - Down pressure | Opener down pressure: 105 lb./opener Press wheel down pressure: 65 lb. at 1500 psi |

| Shanks - Spacing | 9 in. 22.8 cm |

| Mainframe - Centerframe width | 3.56 m 11-ft. 8-in. |

| Clearance - Fore-and-aft | 134 in. 3.51 m |

| Key Specs - Working widths | 28 ft 8.7 m |

| Key Specs - Underframe clearance | 24 in. 60.9 cm |

| Key Specs - Mainframe - Centerframe width | 11-ft. 8-in. 3.56 m |

| Transport position - Transport clearance | With sweep extenders: 16.26-in. (413 mm) Without sweep extenders: 17.26-in. (438 mm) |

| Shanks - Trip force | 200 lb 890 N |

| Sizes - Working widths | 8.53 m 28 ft |

| Mainframe - Size | 28 ft 8.7 m |

| Opener - Spacing | 6-in. (15.2 cm) or 7.5-in. (19.1 cm) |

| Transport position - Height | Maximum height: 12-ft. 9.3-in (3.90 m) Minimum height: 11-ft. 4.3-in (3.46 m) |

| Clearance - Underframe clearance | 24.1 in. 60.9 cm |

| Opener - Quantity | 46 on 7.5-in. spacing 56 on 6-in. spacing |

| Mainframe - Rockshaft | 5.5 x 0.312-in. 140 x 7.92 mm |