STS10 Hagie™ Self-Propelled Sprayer

- John Deere

- Agriculture

Find Your Nearest Location

Key Features & Specs

- Full-season versatility in one machine

- Reduce turn radius and crop damage with all-wheel steer

- Perform late-season applications with Tall Crop Package

- Avoid crop damage and stay on track with AutoTrac™ Vision & RowSense

- Use information with John Deere Integrated Technologies

- Engine hp 300 (221 kW)

- Solution Capacity 1,000 gallons (3,800 L)

- Boom Sections 9

- Application Speed 20 mph (32 km/h)

- Transport Speed 35 mph (56 km/h)

- Boom Width up to 120 feet (36.6 m)

- + Expand All

- - Close All

-

John Deere Connected Support™ prevents downtime and efficiently resolves issues with revolutionary technology-based solutions

Connected Support technology

Connected Support technology

When you buy John Deere equipment, you expect reliability. You also know that problems can happen, and a product is only as good as the support behind it. That’s why John Deere equipment is prepared with technology that senses potential issues and can alert you and your dealer promptly—in the cab or anywhere you are.

John Deere Connected Support is a revolutionary change to support that leverages technology and the connectivity of JDLink™ telematics to prevent downtime and resolve problems faster. These tools decrease downtime by an average of 20 percent, enabling faster responses to unexpected problems and reducing technician trips to your machine. For some issues, unplanned downtime can even be prevented altogether through prediction of the issue.

With your permission, John Deere Connected Support:- Keeps you running by monitoring machine health and promptly alerting you and your dealer of issues

- Saves time by remotely viewing in-cab displays, reducing trips to the machine

- Reduces or even eliminates technician trips to a machine through remote diagnostic and remote software reprogramming capabilities

- Connects experts with the information needed to respond to downtime faster and prevent it altogether

With more than a decade of experience leveraging connectivity to solve problems, no one else has the experience, tools, and knowledge to keep you running as John Deere and your John Deere dealer can. Connected Support is an in-base feature on all John Deere products with factory- or field-installed JDLink.

-

Frame and axles

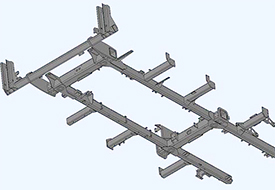

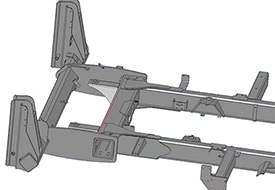

Chassis mainframe

Chassis mainframe

Horizontal cross-through axle tube

Horizontal cross-through axle tube

The STS Series mainframe design features horizontal cross-through axle tubes, as well as boom and platform mounts on weldment.

- 144.8-cm (57-in.) mainframe width (from outside of each mainframe tube)

- 301-cm (118.5-in.) mainframe width (from outside of each boom cradle weldment)

- 183-cm (72-in.) ground clearance

-

Hagie™ STS Series engines

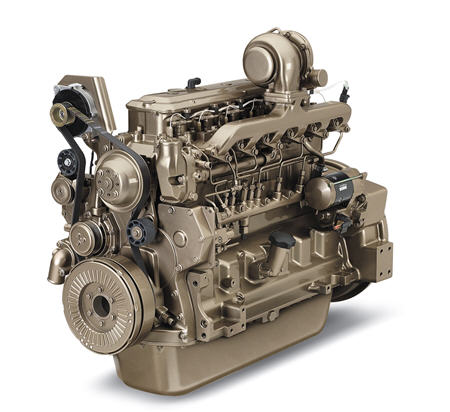

John Deere PowerTech™ PSS 6.8-L (415-cu in.) engine

PowerTech™ PSS 6.8L (415-cu in.) engine

PowerTech™ PSS 6.8L (415-cu in.) engine

Beginning with model year 2019, the Hagie STS10 and STS12 Sprayers utilize the John Deere PowerTech 6.8L (415-cu in.) diesel engine. This engine offers 208.8 kW (280 hp) with a peak power of 223.7 kW (300 hp) in the STS10 and 223.7 kW (300 hp) in the STS12. The reliable performance of these engines couples well with the drive system on the STS Sprayers to provide the operator excellent power on demand.

Engine location

Rear-mounted engine

Rear-mounted engine

The rear-mounted engine keeps constant weight to offset the spray boom and leaves space in the center of machine for the varying weight of fuel and rinse tanks. This allows for better coolant airflow and reduction of cab noise.

Hagie is a trademark of Hagie Manufacturing Company, LLC and similar to John Deere branded equipment, John Deere will also support Hagie equipment.

-

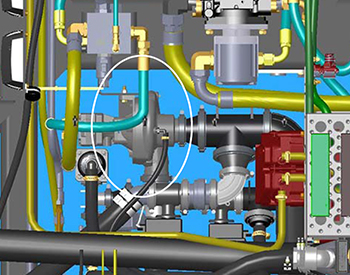

Solution tank, pump, and pump switch

The solution system is a constantly monitored, continuously adjusted, computer-controlled system. The cab-mounted digital spray system console receives information from various inputs to help determine L/ha (gpa) and L/min (gpm).

Solution tank

Solution tank

Solution tank

Sprayer model Tank capacity Tank type STS10 3785 L (1000 gal.) Stainless-steel tank STS12 4542 L (1200 gal.) Stainless-steel tank STS14 5299 L (1400 gal.) Stainless-steel tank STS16 6056 L (1600 gal.) Stainless-steel tank Solution pump

Solution pump

Solution pump

The Hypro® 9306C-HM1C-BU solution pump (located beneath center of machine) is a centrifugal-type, hydraulically-driven pump that is controlled by the solution pump control valve and the spray system console. It comes with silicon-carbide seals, 7.6-cm (3-in.) inlet plumbing and 5.1-cm (2-in.) outlet plumbing.

The solution pump draws solution out of the tank at the rate determined during calibration. It dispenses solution through the many valves and hoses that make up the spray system and also dispenses fluids through the agitation and rinse systems.

Solution pump switch

Solution pump switch

Solution pump switch

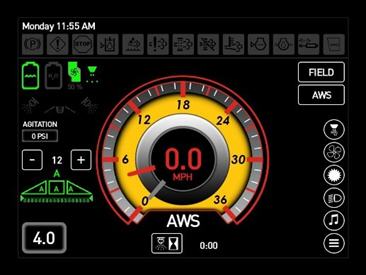

Machine control display - Home

Machine control display - Home

The solution pump switch is located on the side console and is used to turn the solution pump on and off.

NOTE: When the solution pump is on, a solution pump indicator (located on the machine display home page - field mode) will be illuminated.Hypro is a trademark of Pentair Flow Technologies, LLC.

-

STS Series hybrid spray booms

STS Series Sprayer booms

STS Series Sprayer booms

The spray booms are controlled by an electrohydraulic system. This system consists of operator-manipulated switches (located on the side console and the hydrostatic drive control handle) and hydraulic cylinders (attached to the booms), which provide lift, level, and horizontal extension. Hybrid booms are available in widths of 27.4 m, 30.5 m, 36.6 m, and 40.2 m (90 ft, 100 ft, 120 ft, and 132 ft).

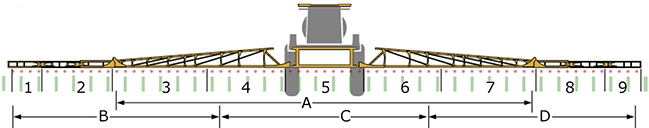

The spray booms are offered in a variety of configurations depending on the model and the producer's application needs.27.4-m (90-ft) boom with 38.1-cm (15-in.) row spacing

Numerical values key:

- Section one

- Section two

- Section three

- Section four

- Section five

- Section six

- Section seven

Alphabetical values key:

- 18.3-m (60-ft) 24-row planter

- 9.1-m (30-ft) 12-row planter

- 9.1-m (30-ft) 12-row planter

- 9.1-m (30-ft) 12-row planter

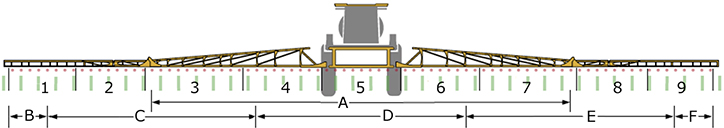

30.5-m (100-ft) boom with 38.1-cm (15-in.) row spacing

Numerical values key:

- Section one

- Section two

- Section three

- Section four

- Section five

- Section six

- Section seven

- Section eight

- Section nine

Alphabetical values key:

- 18.3-m (60-ft) 24-row planter

- 3.05 m (10 ft)

- 9.1-m (30-ft) 12-row planter

- 9.1-m (30-ft) 12-row planter

- 9.1-m (30-ft) 12-row planter

- 3.05 m (10 ft)

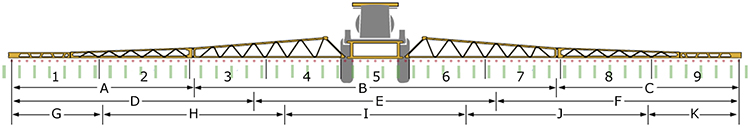

36.6-m (120-ft) boom with 38.1-cm (15-in.) row spacing

Numerical values key:

- Section one

- Section two

- Section three

- Section four

- Section five

- Section six

- Section seven

- Section eight

- Section nine

Alphabetical values key:

- 9.1 m (30 ft)

- 18.3-m (60-ft) 24-row planter

- 9.1 m (30 ft)

- 9.1-m (30-ft) 16-row planter

- 9.1-m (30-ft) 16-row planter

- 9.1-m (30-ft) 16-row planter

- 4.6 m (15 ft)

- 9.1-m (30-ft) 12-row planter

- 9.1-m (30-ft) 12-row planter

- 9.1-m (30-ft) 12-row planter

- 4.6 m (15 ft)

Boom configurations

Hybrid boom width Boom

locationNumber of sections Wet boom nozzle

spacing27.4 m (90 ft) Front Seven

38 or 51 cm

(15 or 20 in.)30.5 m (100 ft) Front Nine

38 or 51 cm

(15 or 20 in.)36.6 m (120 ft) Front Nine

38 or 51 cm

(15 or 20 in.)40.2 m (132 ft) Front Nine

38, 51, or 56 cm

(15, 20, or 22 in.)Materials used in boom construction:

- 27.4-m, 30.5-m, 36.6-m, and 40.2-m (90-ft, 100-ft, 120-ft, and 132-ft) booms – steel/aluminum hybrid

Boom

| Plumbing material | Stainless steel |

| Automatic boom height | NORAC |

| Boom sections | 7 or 9 sections on booms - 27/36 m 90/120 ft |

| Breakaway width | For 27-m (90-ft) booms - 3 m 10 ft For 30-m (100-ft) booms - 3.8 m 12.5 ft For 36-m (120-ft) booms - 4.6 m 15 ft |

| Ground height adjustment | 46 to 264 cm 18 to 104 in. |

| Boom length options | 18/24/27, 18/30, or 36/40 m 60/80/90, 60/100, or 120/132 ft |

Chassis

| Dry compatible | No |

| Suspension | Independent air-ride |

| Front tires | 380/85R46, 320/90R50, or 320/105R54 |

| Rear tires | 380/85R46, 320/90R50, or 320/105R54 |

| Flotation tires | LSW 680/55R42 |

| Hydraulic tread adjust | Optional |

| Parking brake | Integrated in final drives |

| Primary brakes | Drive system dynamic braking |

| Ladder raise/lower | Hydraulic |

| Turning radius | 5.6 m 18.5 ft |

| Wheel tread spacing | 305 to 386 cm 120 to 152 in. |

| Crop clearance with standard tires | 183 cm 72 in. |

| Total weight with 120-ft boom | 12,147 kg 26,780 lb |

| Wheel base | 356 cm 140 in. |

| Total weight with 90-ft boom | 12,265 kg 27,040 lb |

Drivetrain

| Type | Hydrostatic |

| Drive | Full-time four-wheel drive (4WD) |

| Shifting | Infinitely variable |

| Hydraulic reservoir capacity | 190 L 50 gal. |

| Transport speed, maximum | 56 km/h 35 mph |

| Spray speed range | 0.8 to 32 km/h 0.5 to 20 mph |

Engine

| Emissions | Final Tier 4 (FT4) |

| Number of cylinders | Six |

| Alternator | 200 amp |

| Fuel tank capacity | 510 L 135 gal. |

| Displacement | 6.8 L 415 cu in. |

| Peak rated power | 208 kW 280 hp |

| Diesel exhaust fluid (DEF) tank capacity | 37.9 L 10 gal. |

Key Specs

| Suspension | Independent air-ride |

| Spray speed range | 0.8 to 32 km/h 0.5 to 20 mph |

| Total weight with widest boom | 12,147 kg 26,780 lb |

| Crop clearance with standard tires | 183 cm 72 in. |

| Transport speed, maximum | 56 km/h 35 mph |

| Rinse tank capacity | 380 L 100 gal. |

| Boom length options/Material | 18/24/27, 18/30, or 36/40 m 60/80/90, 60/100, or 120/132 ft |

| Engine | Peak rated power 208 kW 280 hp |

| Solution system - Capacity | 3700 L 1000 gal. |

Options

| Air compressor | Onboard air |

| Foam marker capacity | 11.35 L 3 gal. |

Solution system

| Tank material | Poly, stainless steel |

| Automatic section control | Optional |

| Solution system control | John Deere |

| Chemical injection method | Raven Sidekick - optional |

| Chemical eductor | Optional |

| Pressure strainer | 50 mesh |

| Boom strainer | Standard 80 mesh |

| Rinse tank capacity | 380 L 100 gal. |

| Quick fill size | 7.6 cm 3 in. |

| Chemical eductor capacity (size) | 30.3 L 8 gal. |

| Capacity | 3700 L 1000 gal. |

| Flow meter size | 5.8 cm 2 in. |

| Fill location | Front standard Side/rear optional |

Additional information

| Date collected | 08-May-2018 |