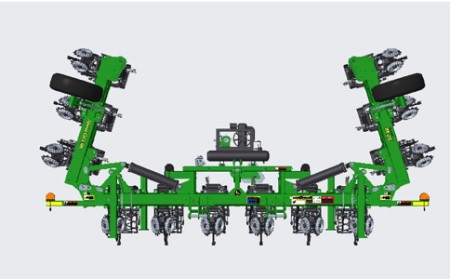

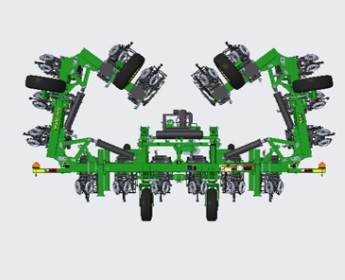

John Deere ST18 Drawn Strip-Till Solution

Agriculture

- 18-row offerings

- Compatible with 20-inch or 22-inch rows

- Shank or coulter options to fit your needs

- Air adjust row cleaners

Equipment Features

Featured List

- Configurations: Drawn

- Spacing Options: 20 in. (50.8 cm) or 22 in. (55.9 cm)

- Fertilizer Capacity: 10 tons

- Working Depth: Shanks up to 11" (27.9 cm)

Coulters up to 6" (15.24 cm) - Working Speed: Coulters 7 to 10 mph (9.7 to 16 km/h)

Shanks 5 to 8 mph (8 to 13 km/h)

Featured Content

|

Model |

Row Spacing |

Number of Rows |

Working Depth |

Row Unit Travel |

|

ST12 Integral – 9 m (30 ft) |

762 mm (30 in) |

12 |

Up to 152 mm (6 in.) with dual coulter, up to 279 mm (11 in.) using shanks |

203 mm (8 in) |

|

ST16 Integral – 12 m (40 ft) |

16 |

|||

|

ST12 Drawn – 9 m (30 ft) |

12 |

|||

|

ST16 Drawn – 12 m (40 ft) |

16 |

|||

|

ST18 Drawn – 9 m (30 ft) |

508 mm (20 in) |

18 |

||

|

ST18 Drawn – 10 m (33 ft) |

559 mm (22 in) |

18 |

ST12 Integral row unit with shanks

ST16 Drawn row unit with dual coulters

ST12 Integral frame

ST16 Drawn frame

|

Model |

Working Width |

Transport Width |

Transport Height |

Weight |

Operating Clearance |

Frame Sections |

|

ST12 Integral |

9.1 m (30 ft) |

6.3 m (20 ft 9 in) |

3.7 m (12 ft 2 in) |

5,443 kg (12,000 lb) |

508 mm (20 in) |

3 |

|

ST16 Integral |

12.2 m (40 ft) |

6,654 kg (14,670 lb) |

5 |

|||

|

ST12 Drawn |

9.1 m (30 ft) |

5.4 m (17 ft 7 in) |

4.3 m (14 ft 1 in) |

13,245 kg (29,900 lb) |

482.6 mm (19 in) |

3 |

|

ST16 Drawn |

12.1 m (40 ft) |

4.5 m (14 ft 9 in) |

14,288 kg (31,500 lb) |

|||

|

ST18 Drawn |

9.1 m (30 ft) |

4.6 m (15 ft) |

16,103 kg (35,500 lb) |

|||

|

ST18 Drawn |

10.1 m (33 ft) |

16,556 kg (36,500 lb) |

ST12 Integral 3-section frame

ST16 Integral 5-section frame

Integrated fertilizer tanks on drawn model

Overview

Applying fertilizer with a strip-till tool is becoming more common as customers seek to reduce compaction, increase efficiency, and improve profitability. The ST Drawn models have two integrated fertilizer tanks which have a capacity of 200 cu ft (160 bushels) each. The tool can carry up to 9,072 kg (20,000 lb.).

Benefits

The ST Series fertilizer delivery system is equipped with stainless steel meters, integrated scales, and other technologies that enable optimal reliability and durability in the customer’s operation.

Overview

In-cab controls and adjustable air regulators

Several functions of the strip-till tool can be controlled and regulated from the cab using a switch box that houses the following functions:

- Fold: Folds and unfolds the toolbar; enables lift wheel, inner wing, and outer wing switches

- Tilt: Tilts the toolbar in the fold section

- Scales: Turns on the scales with a dry system

- Hydraulic drives/AC: Turns on the power to operate the fertilizer drives and air compressor

- Zone cleaner lift: Raises and lowers row cleaners

Benefits growers with rolling terrain, contours, or other field conditions that may affect implement drift. It ensures consistent strip alignment when making headland turns.

Enables plug and play functionality with the John Deere Active Implement Guidance™ Ready option. For more information, see Active Implement Guidance in the Sales Manual.

The table below identifies which hitches are compatible with the integral and drawn models.

|

Model |

Rows |

Hitch Type |

Category |

Minimum Horsepower Requirements |

|

Integral |

12-row |

Integral 3 pt. connection (with quick hitch) |

Category 4/4N |

224 kW (300 hp) |

|

16-row |

299 kW (400 hp) |

|||

|

Drawn |

12-row |

Drawn connection |

Category 4/4HD/5 |

268 kW (360 hp) |

|

16-row |

358 kW (480 hp) |

|||

|

18-row |

403 KW (540 hp) |

Hydraulic control on the front of the integrated steerable hitch

Hitch pivot point at the rear axle

The importance of planting into the strips

- Planting the seed into a residue free strip allows for quicker and more uniform plant emergence

- Placing the seed into the nutrient zone allows plant roots to fully access and utilize nutrients

How does precision technology enable accurate seed placement within the strips?

With so much at stake, getting it right is not an option. Utilizing the suite of precision guidance tools, executing perfectly placed strips has never been easier.

John Deere Active Implement Guidance™ system

Utilizes integrated steerable hitch on drawn units to steer the implement to the guidance line provided by the StarFire™ receiver. Without Active Implement Guidance, implements can drift due to varying soil conditions and sloping terrain. Order as Active Implement Guidance ready to include the required hydraulic cylinder, sensor mount, linkage, and hardware.

Hydraulic control on the front of the integrated steerable hitch

Steerable hitch pivot at the rear axle

Uses data from the first strip-till pass to automatically create full-field guidance lines for the secondary passes such as planting, spraying, and harvest.

Enables StarFire receivers to share information when paired using implement guidance. This allows an implement’s StarFire receiver with lower accuracy to take advantage of the higher accuracy used by the tractor receiver.

StarFire 7000 Receiver on implement

Increases productivity in subsequent crop passes by reducing overlap and maximizing inputs.

Creates guidance lines from the dimensions of the exterior boundary and track spacing. Allows the operator to work around fence lines and field boundaries with boundary track mode.

For additional information, see Work around fence lines and field boundaries with boundary track mode.

Overview

The row-unit tillage depth is set based on achieving the desired outcome of the following factors: compaction management, fertilizer placement and berm creation. Depth settings vary between dual coulter and shank tillage options.

To enable consistent operating depths across the machine, the downforce system is split into two circuits: one for row-units that are running in wheel tracks (blue airline) and one for the remaining row-units (black airline). This allows for independent control of the rows running in a potentially more compacted portion of the machine. Operators can observe the parallel linkage position across the rows while operating and adjust the downforce as needed.

Air regulators for row unit downforce

- Yellow: Row cleaner lift pressure

- Green: Row cleaner down pressure

- Black: Row-unit down pressure (rows not running in wheel tracks)

- Blue: Row-unit down pressure (rows running in wheel tracks)

Dual coulters

Operating depth is set using the air pressure regulators mounted in the cab. These control the amount of pressure in the downforce airbag(s) located on each row-unit. Operating depth can be set from 5 cm (2 in.) to 15 cm (6 in.) by varying the downforce pressure.

Shanks

Pin-adjust depth on shank equipped row-units

Operating depth is adjusted on shank equipped row-units with two pins. The shallow setting is approximately 23 cm (9 in), and the deep setting is approximately 28 cm (11 in.).

Row cleaners

Optional floating row cleaners equipped with a pneumatic cylinder are available. They are easily adjusted with the cab mounted air regulators to adapt to varying residue conditions.

ST Drawn model with coulters

ST Integral model with shanks

Overview

Strip-till is a growing minimum tillage solution that clears residue and tills 203 mm (8 in.) to 254 mm (10 in.) strips, leaving the rest of the row undisturbed. This allows operators to till where tillage matters, produce a nutrient-rich welcoming seed environment, reduce input costs, maintain yield, and maximize profitability.

Benefits

Whether an operator prepares ground in the spring or fall, just one pass across the field with the John Deere strip-till tool will complete compaction management, nutrient application, and seedbed preparation, all in one pass. In many situations, producers moving from conventional tillage to strip-till have reduced trips across the field by as many as four passes. By only making one pass across the field, sustainability is at its peak. Strip-till reduces soil erosion, minimizes nutrient run-off, and conserves moisture, all while reducing input costs for the customer. Maximizing the efficiency of every liter or gallon of fuel is critical for boosting the profitability of farming operations.

Additional details

John Deere ST Series Options

Customers can choose between dual coulter or shank tillage. Coulters will allow earlier field access to accelerate seedbed preparation. Shanks will increase soil fracturing in tough field conditions and allow for anhydrous ammonia application. Four bolts per row unit allow for simple change over between shank and dual coulter configurations. More ST Series options are listed below.

|

Model |

Benefit |

Number of Rows |

Row Spacing |

Fertilizer Capabilities |

|

ST Integral |

Maneuver easily in the field and in tight spaces |

12, 16 |

762 mm (30 in.) |

· Compatible with select third-party dry fertilizer application systems · Anhydrous application using shank |

|

ST Drawn |

Reduce number of passes in the field by applying fertilizer while tilling |

12, 16 |

762 mm (30 in.) |

· Integrated dual 4,535 kg (5-ton) dry fertilizer tanks · Anhydrous application using shank |

|

18 |

508 mm (20 in.) 559 mm (22 in.) |

John Deere ST Series offers the option of coulters or shanks with the ability to switch between them in changing field conditions.

Dual coulters

Two vertically mounted blades spaced 127 mm (5 in) apart with a maximum working depth of up to 152 mm (6 in). There are several benefits to utilizing dual coulters such as:

- Industry exclusive in-cab depth control

- Productivity enhancement with working speeds up to 16 km/h (10 mph)

- Uniform fertilizer distribution over the entire width of the strip, preventing hot band of fertilizer

- Minimal soil disturbance and residue cutting capabilities

| Dual coulter option | Level of soil disturbance |

| 508 mm (20 in) 13-Wave Blades | Standard |

|

508 mm (20 in) 18-Wave Front and |

Medium |

|

508 mm (20 in) 8-Wave Front and |

Aggressive |

508 mm (20 in) 13-wave blade

508 mm (20 in) 13-wave front and 13-wave rear dual coulter

508 mm (20 in) 18-wave blade

508 mm (20 in) 18-wave front and 13-wave rear dual coulter

508 mm (20 in) 8-wave blade

508 mm (20 in) 13-wave front and 8-wave rear dual coulter

Shanks

Shanks have 13 mm (half-inch) NH3 tubes and 2 to 4 vapor knives. A shank is preferred for deeper nutrient banding and fracturing compacted soil layers and can be used for anhydrous application to place the nutrients in the upper area of the root zone. Operating depth is adjusted on shank equipped row units with two pins. The shallow setting is approximately 230 mm (9 in), and the deep setting is approximately 280 mm (11 in).

Shank located between the lead coulter and containment coulter