H541 Air Hoe Drill

- John Deere

- Air Drills

Key Features & Specs

- See the flow of seed & fertilizer from the cab with RelativeFlow™ blockage monitoring

- Positive depth control features and options

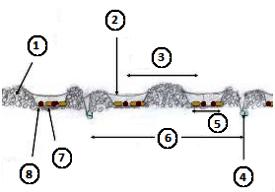

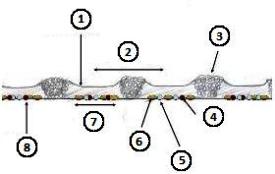

- Choice of ground-engaging openers

- Longer machine life with flexible frame

- Transport Width 20 ft.

- Opener Ground-engaging knife

- Fertilizer Placement In Furrow

- Working Width 40 ft., 41 ft. 8 in.

-

Row Spacing

7.5 in. (19.05-cm)

10-in. (25.4-cm)

12.5-in. (31.75-cm)

Dimensions

| Spacing and width #8 | Working width 15.2 m 50 ft Transport height with harrow 5.38 m 17.65 ft Transport height without harrow 5.38 m 17.65 ft Minimum temporary height reduction with sweeps 508 mm 20 in. Nominal inner wing width (between wing-fold pivots) 3.08 m 10.10 ft Weight Weight with typical options: 12,450 kg 27,450 lb Spacing: 30.5 cm 12 in. Width: 15.2 m 50 |

| Spacing and width #9 | Working width 19.0 m 62.5 ft Transport height with harrow 5.99 m 19.67 ft Transport height without harrow 5.99 m 19.67 ft Minimum temporary height reduction with sweeps 483 mm 19 in. Nominal inner wing width (between wing-fold pivots) 4.14 m 13.59 ft Weight Weight with typical options: 14,320 kg 31,575 lb Spacing: 30.5 cm 12 in. Width: 19.0 m 62.5 ft |

| Spacing and width #5 | Working width 15.2 m 50 ft Transport height with harrow 5.04 m 16.53 ft Transport height without harrow 5.04 m 16.53 ft Minimum temporary height reduction with sweeps 508 mm 20 in. Nominal inner wing width (between wing-fold pivots) 3.08 m 10.1 ft Weight Weight with typical options: 13,540 kg 29,850 lb Spacing: 25.4 cm 10 in. Width: 15.2 m 50 ft |

| Nominal mainframe width (between wing-fold pivots) | 4.19 m 13.75 ft |

| Spacing and width #1 | Working width 12.4 m 4.625 ft Transport height with harrow 5.90 m 19.36 ft Transport height without harrow 5.90 m 19.36 ft Minimum temporary height reduction with sweeps 457 mm 18 in. Nominal inner wing width (between wing-fold pivots) 3.08 m 10.1 ft Weight Weight with typical options: 11,250 kg 24,800 lb Spacing: 19.05 cm 7.5 in. Width: 12.4 m 40.625 ft |

| Road clearance with sweep | 40.6 cm 16 in. |

| Transport width | 6.1 m 20 ft |

| Spacing and width #7 | Working width 12.7 m 41.67 ft Transport height with harrow 5.99 m 19.66 ft Transport height without harrow 5.99 m 19.66 ft Minimum temporary height reduction with sweeps 457 mm 18 in. Weight Weight with typical options: 9,640 kg 21,250 lb Spacing: 30.5 cm 12 in. Width: 12.7 m 41.67 ft |

| Number of seed openers | Primary air package configurations for the 1830 |

| Spacing and width #2 | Working width 15.4 m 50.625 ft Transport height with harrow 16.31 ft 4.97 m Transport height without harrow 4.97 m 16.31 ft Minimum temporary height reduction with sweeps 508 mm 20 in. Nominal inner wing width (between wing-fold pivots) 3.08 m 10.10 ft Weight Weight with typical options: 14,900 kg 32,850 lb Spacing: 19.05 cm 7.5 in. Width: 15.4 m 50.625 ft |

| Spacing and width #3 | Working width 18.1 m 59.375 Transport height with harrow 5.72 m 18.76 ft Transport height without harrow 5.72 m 18.76 ft Minimum temporary height reduction with sweeps 508 mm 20 in. Nominal inner wing width (between wing-fold pivots) 3.82 m 12.55 ft Weight Weight with typical options: 16,330 kg 36,000 lb Spacing: 19.05 cm 7.5 in. Width: 18.1 m 59.375 ft |

| Spacing and width #4 | Working width 12.2 m 40 ft Transport height with harrow 5.86 m 19.22 ft Transport height without harrow 5.79 m 19.01 ft Minimum temporary height reduction with sweeps 457 mm 18 in. Weight weight with typical options: 10,330 kg 22,775 Spacing: 25.4 cm 10 in. Width: 12.2 m 40 ft |

| Spacing and width #6 | Working width 18.8 m 61.67 ft Transport height with harrow 5.98 m 19.62 ft Transport height without harrow 5.91 m 19.40 ft Minimum temporary height reduction with sweeps 483 mm 19 in. Nominal inner wing width (between wing-fold pivots) 4.14 m 13.59 ft Weight Weight with typical options: 15,340 kg 33,825 lb Spacing: 25.4 cm 10 in. Width: 18.8 m 61.67 ft |