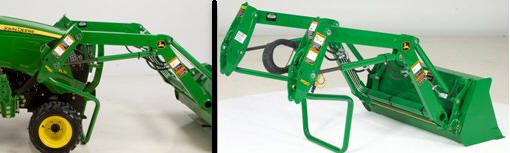

120R Loader

- John Deere

- Agriculture

Key Features & Specs

- Compatible with the 1023E, 1025R and 2025R tractors

- Quik-Park stands for easy attachment and removal

- 754 lbs. (342 kg) of lift capacity

- 72 in. (1,828 mm) of lift height

- Lift Capacity 754 lbs. (342 kg)

- Lift Height 72 in. (1828 mm)

Loader

| Bucket used | General Material 1250 |

| Bucket weight | 70.2 kg 154 lb |

| Lift capacity at full height | Measured at pivot (U) 342 kg 754 lbMeasured at 500 mm ahead of pivot (V) 236 kg 520 lb |

| Lift capacity at 59 in. (1500 mm) | Measured at pivot (W) 337 kg 743 lbMeasured at 500 mm ahead of pivot (X) 263 kg 580 lb |

| Boom breakout force | Measured at pivot (Y) 826 kg 1823 lbMeasured at 500 mm ahead of pivot (Z) 599 kg 1320 lb |

| Bucket rollback force capacity | At maximum height (VV) 741 kg 1634 lbAt 59-in. (1500-mm) lift height (XX) 770 kg 1700 lbAt ground-level line (ZZ) 819 kg 1807 lb |

| Dimensions | Maximum lift height (A) 1828 mm 72 in.At full height - bucket level(B) 1671 mm 65.8 in.At full height - bucket dumped (C) 1371 mm 54 in. |

| Overall length (I+F), ft (m) | 2786 mm 107.9 in. |

| Digging depth (H) | -88 mm -3.2 in. |

| Reach | At maximum height (D) 626 mm 24.7 in.At ground level - bucket level (F) 1186 mm 46.7 in. |

| Bucket angle | Dump angle, degrees (E) -40.5 degree (angle)Rollback angle, degrees (G) 29.87 degree (angle)Dump angle, ground -115.4 degree (angle) |

| Cycle times | Loader raise, seconds 3.2 secondsLoader lower, seconds 3.2 secondsBucket dump, seconds 3.1 secondsBucket rollback, seconds 2.2 seconds |